Small goods/food lift "Service Line"

The "SERVICE Line" food lift solves your transport problems in commercial areas with a lifting height of up to 60 metres. The small goods/food lift has electronic controls with call and send functions and an acoustic arrival signal at every stop. With a selectable load capacity of 50 kg, 100 kg or 300 kg, meeting rooms or other floors can be conveniently supplied with open food or drinks directly from the kitchen at any time. The food lift is made entirely from high-quality materials sourced in Germany, guaranteeing a long service life.

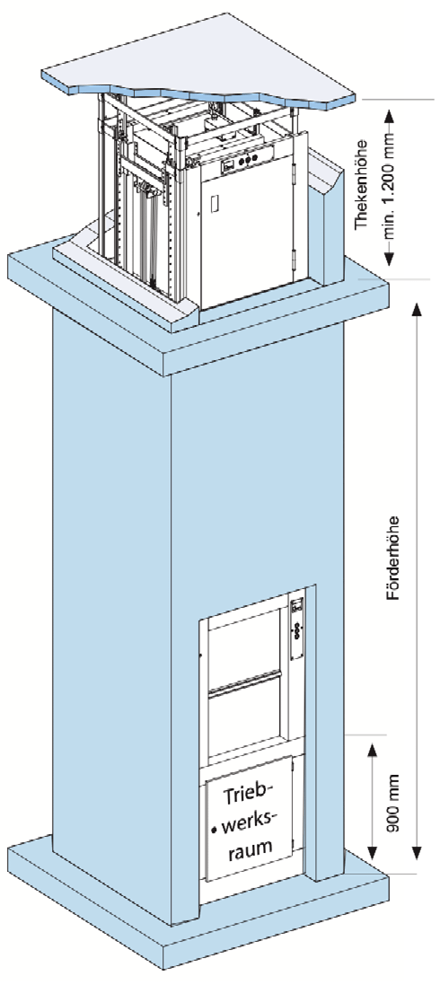

It can also be designed as a counter lift at the top stop.

But the food lift is not only the right choice for restaurants, hotels or event locations. Thanks to its maximum load capacity of 300 kg, it can also be used as a small goods lift in logistics, whenever a load height up to the height of the handrail is required.

For private construction projects, we offer simplified, very affordable package deals.

Advantages and areas of application

- Can be used for up to 20 floors and a lifting height of 60 metres

- Load capacity: 50 kg, 100 kg or 300 kg

- Allows the transport of open food and beverages

- Ready for use without separate TÜV approval

- Thanks to its modular design, it can be assembled in just a few hours

- Requires little floor space thanks to extremely compact design

- Can be picked up and dispatched from any stop via electronic control

- Saves a lot of time and is easy on the legs

- Operating speed up to Vmax = 1 m/s

- 30-year spare parts supply

Food lifts Examples

Technical equipment

Load capacities:

a 50 kg, 100 kg or 300 kg

Interior dimensions of cabin:

(in 50 mm increments, width + depth)

(in 100 mm increments, height)

Width: minimum 300 mm, maximum 1,000 mm,

Depth: minimum 320 mm, maximum 1,000 mm,

Height: minimum 600 mm, maximum 1,200 mm

Shaft internal dimensions:

(in 50 mm increments, same as cabin)

Width: minimum 620 mm, maximum 1,320 mm,

Depth: Minimum 500 mm, maximum 1,180 mm

Loading/access:

One-sided (front loader) or opposite (through loader) or 90° across the corner to the left or right

Shaft doors:

2-part, horizontally divided, vertically opening sliding doors

Operating speed:

0.10 m/s, 0.15 m/a, 0.25 m/s, 0.30 m/s, 0.45 m/s, 0.63 m/s and 1.0 m/s

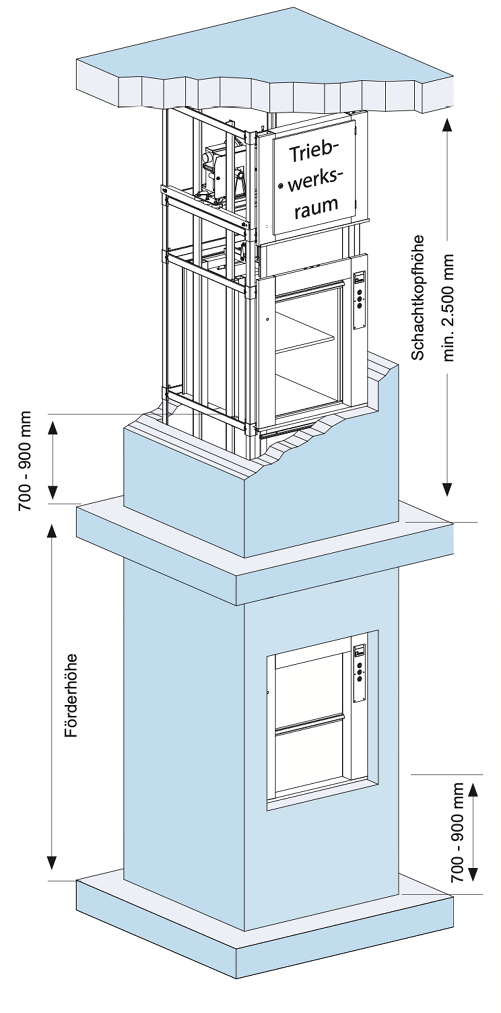

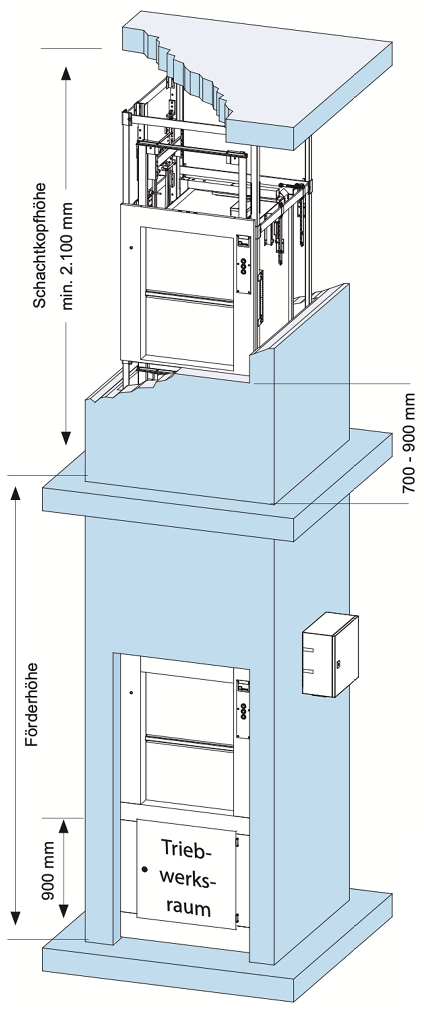

Drive unit arrangement:

Top of shaft head or bottom of shaft base or bottom left or right next to the shaft

Surfaces:

Hot-dip galvanised sheet steel or brushed stainless steel (material 1.4016 or 1.4301 or 1.4571).

All visible surfaces can also be powder-coated in RAL colours according to customer requirements.

Optional equipment

- Safety device – mandatory if there are accessible rooms below the lift

- Additional cabin intermediate floors (removable)

- Cabin lighting

- Heated cabin floor, continuously adjustable up to approx. 80 °C

- Cabin closure as contact-proof aluminium roller shutter

- Cabin closure as contact-protected, split, vertically opening stainless steel sliding door

- Automatic, electrically opening shaft doors in conjunction with PLC control

- Automatic, electrically opening cabin doors in conjunction with PLC control

- Stainless steel frame cladding

- Various child safety devices

- Shaft sliding doors in accordance with EN81-58 E120 (120 minutes fire resistant)

- Shaft sliding doors in accordance with EN81-58 EW60 (60 minutes fire resistant)

- Double-walled shaft sliding doors in accordance with EN81-58

Special equipment

- Design as counter lift

- Version as ship lift

- Lifts with rope drum drive on the left or right side of the shaft

- Shaft frame design for on-site glazing

- Design with hygiene cabin

- Small goods/food lifts with increased operating speed of 0.63 m/s, 1.0 m/s in conjunction with frequency-controlled drive and soft start/soft stop or PLC control.

Subject to technical changes. Special dimensions on request.